Introduction

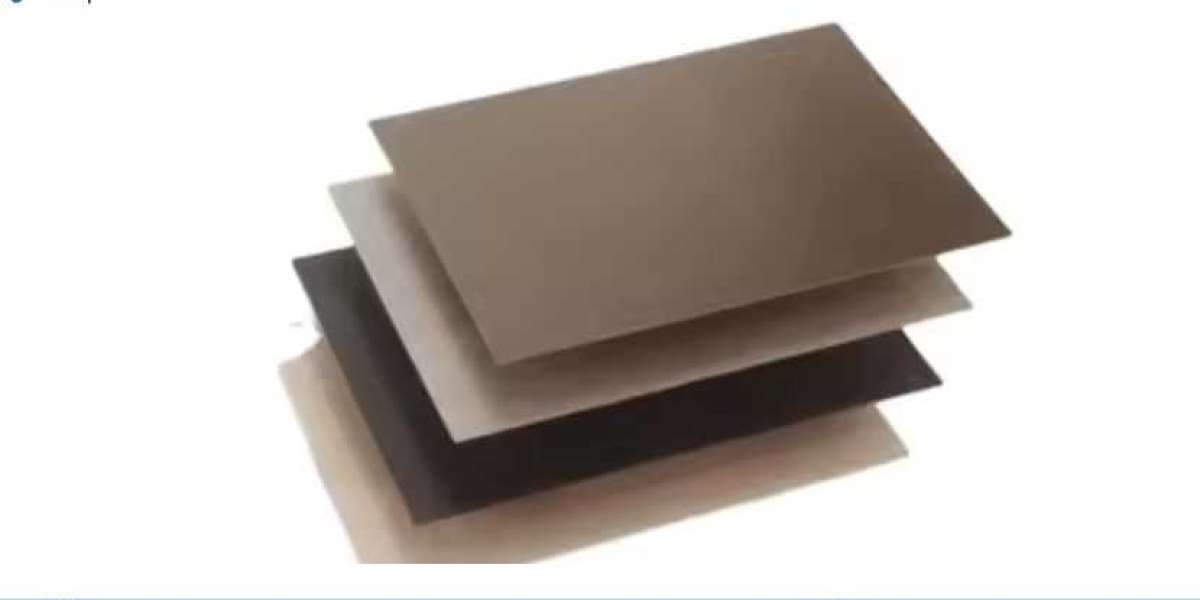

Micanite is a high-performance insulating material derived from mica, a naturally occurring mineral that is widely used in the production of electrical and thermal insulators. Known for its high dielectric strength, heat resistance, and excellent electrical properties, micanite has found a broad range of applications in industries such as electrical, electronics, automotive, aerospace, and more. Micanite is particularly used for making electrical insulation products such as electrical capacitors, transformers, switches, and heating elements.

The global demand for micanite has seen an upward trend, driven by the growth of the electronics and electrical industries. The need for efficient insulation materials in high-tech devices, coupled with the increasing emphasis on energy-efficient technologies, presents an opportunity to set up a micanite manufacturing plant. This Micanite Manufacturing Plant Project Report provides an in-depth analysis of the feasibility, production process, raw material requirements, regulatory considerations, market dynamics, and financial projections for establishing a micanite manufacturing facility.

Market Overview

Global Market for Micanite

The global market for micanite is primarily driven by the rising demand for electrical insulation materials in various industries, particularly the electronics and electrical power sectors. With the rapid advancement of technology in these sectors, there is a growing need for materials that offer superior thermal and electrical insulating properties.

Key factors influencing the market include:

Growth of the Electronics Industry: The electronics industry continues to evolve with the proliferation of consumer electronics, smartphones, and other devices. Micanite is crucial in the production of high-performance electronic components that require reliable insulation.

Rising Demand in Electrical Power Industry: Micanite is widely used in the manufacture of electrical transformers, capacitors, and other power distribution equipment. The increasing demand for electrical power infrastructure, especially in emerging economies, is boosting the demand for micanite.

Development in Automotive and Aerospace Sectors: The automotive industry, especially with the rise of electric vehicles, and the aerospace sector require high-performance materials like micanite for insulation in various components.

Emphasis on Energy-Efficient Technologies: The global focus on reducing energy consumption and improving energy efficiency has led to a rise in demand for insulation materials that can ensure high performance under various conditions, which micanite provides.

Get a Free Sample Report with Table of Contents@

Regional Insights

Asia-Pacific: The Asia-Pacific region is a major consumer of micanite due to the large electronics manufacturing base, particularly in countries like China, Japan, and South Korea. Additionally, the growth of the power sector in India and other Southeast Asian nations is driving demand for micanite.

North America: The demand for micanite in North America is driven by the growing industrial applications and the high demand for power generation and transmission equipment. The U.S. and Canada remain significant markets for high-performance insulation materials.

Europe: Europe is another key market, with countries like Germany, the UK, and France focusing on energy-efficient technologies and power distribution systems. The automotive and aerospace industries in Europe also contribute to the demand for micanite.

Feasibility Study for Micanite Manufacturing Plant

Site Selection

The first step in establishing a micanite manufacturing plant is selecting an appropriate site. The following factors should be considered during site selection:

Proximity to Raw Material Suppliers: Mica, the primary raw material used in micanite production, should be sourced from local or regional suppliers to minimize transportation costs and ensure a steady supply of high-quality mica.

Regulatory Compliance: The site should comply with local environmental and industrial regulations. The facility must meet the safety, health, and environmental standards set by government authorities to ensure smooth operations.

Availability of Skilled Labor: The location should be near industrial hubs or educational institutions where skilled labor is readily available. Skilled technicians and engineers are crucial for the maintenance of the manufacturing process and the production of high-quality micanite.

Infrastructure and Logistics: The site should have well-developed infrastructure, including transportation networks (roads, railways, ports) for efficient distribution of both raw materials and finished products.

Regulatory Compliance

The manufacturing plant must comply with the following regulatory frameworks:

Environmental Regulations: The facility should adhere to environmental guidelines related to air, water, and waste management. Micanite production may involve high-temperature processes, which require efficient waste disposal and emission control measures.

Occupational Health and Safety (OHS): A strict adherence to OHS standards is crucial to ensure the safety of the workers involved in the production process. This includes compliance with workplace safety protocols, use of personal protective equipment (PPE), and ensuring a safe working environment.

ISO Certification: ISO 9001 (Quality Management Systems) and ISO 14001 (Environmental Management Systems) certifications can add credibility to the manufacturing process and help in ensuring product quality and sustainability.

Raw Materials and Procurement

The primary raw material for micanite production is mica, a naturally occurring mineral. There are two main types of mica used in micanite manufacturing:

- Flake Mica: This is used in the production of high-quality micanite as it has a more uniform structure and better insulating properties.

- Scrap Mica: This is often less pure but still usable in certain applications. It is more cost-effective but may have slightly lower quality than flake mica.

Other materials that may be required include:

- Binding Agents: Used to create the desired consistency and texture in the final micanite product.

- Chemical Additives: Various chemicals may be used to enhance the thermal and electrical properties of micanite.

Long-term contracts with mica suppliers and sourcing raw materials from reliable vendors will ensure a steady and cost-effective supply for the manufacturing plant.

Manufacturing Process

The production of micanite involves several key steps, including the preparation of mica, binding, and curing. The general process is as follows:

Mica Preparation: The mica is cleaned and sorted to remove impurities and fine particles. The mica is then ground into small flakes or powders to prepare it for mixing with other materials.

Mixing with Binding Agents: The prepared mica is mixed with binding agents, which may include resins, adhesives, or other chemicals. The mix is then processed to achieve the desired consistency.

Pressing and Shaping: The mixture is placed into molds and subjected to high pressure to form the desired shape. This step ensures that the mica particles are evenly distributed and the final product is uniform.

Curing: The molded micanite is then cured at high temperatures to harden the material and enhance its insulation properties. This step is crucial for ensuring that the final product can withstand high temperatures and electrical currents.

Finishing and Inspection: After curing, the micanite is inspected for quality and trimmed to the required dimensions. The final product is tested for its thermal and electrical resistance to ensure it meets industry standards.

Workforce Requirements

The manufacturing plant will require a skilled workforce to ensure efficient and smooth operations. Key personnel will include:

- Production Managers: Oversee the entire manufacturing process, ensuring that production targets are met and quality standards are maintained.

- Technicians: Responsible for operating machinery and ensuring that the manufacturing process runs smoothly.

- Quality Control Inspectors: Conduct regular inspections of raw materials, in-process materials, and finished products to ensure compliance with industry standards.

- Maintenance Engineers: Responsible for maintaining and repairing production equipment to prevent downtime and ensure efficient operations.

- Laborers: General workers to assist with packaging, material handling, and other production-related tasks.

Financial Considerations

The financial viability of the micanite manufacturing plant depends on several factors, including initial capital investment, operational costs, and expected revenue. Key financial considerations include:

Initial Investment: The initial investment required to set up the plant will include land acquisition or leasing costs, construction costs, machinery and equipment purchases, and raw material procurement.

Operational Costs: Ongoing costs include labor, raw materials, utilities (electricity, water), and maintenance expenses. These costs should be closely monitored to ensure profitability.

Revenue Projections: Revenue will depend on production capacity, pricing strategy, and demand in various markets. A strong market presence in key industries like electrical, electronics, automotive, and aerospace can drive consistent demand for micanite.

Break-even Analysis: A break-even analysis can help determine the point at which the plant will start generating profits. This will depend on the plant’s production efficiency, cost control measures, and pricing strategy.

Profitability and Return on Investment (ROI): By forecasting revenues and operating costs, the ROI can be calculated to assess the long-term profitability of the project.

Marketing and Distribution Strategy

Once the micanite is produced, it will be sold to various sectors, including:

- Electrical and Electronics Manufacturers: Micanite is widely used in electrical capacitors, transformers, and other power generation and distribution equipment.

- Automotive and Aerospace Industries: High-performance insulation materials like micanite are essential in automotive and aerospace components that require thermal and electrical resistance.

- Industrial Suppliers: The plant can also supply micanite to other manufacturers producing industrial heating elements, switches, and other high-voltage equipment.

A well-developed marketing and distribution strategy, along with a strong network of sales representatives and distributors, will be key to driving the plant’s success.

Explore More Report

https://www.expertmarketresearch.com/articles/top-toys-companies

Media Contact

Company Name: Claight Corporation

Contact Person: Peter Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au