Choosing the right UPVC pipe manufacturer is crucial for ensuring high-quality, durable, and efficient piping solutions. UPVC (Unplasticized Polyvinyl Chloride) pipes are widely used in water supply, irrigation, drainage, and industrial applications due to their excellent chemical resistance, durability, and cost-effectiveness. However, not all manufacturers adhere to the same standards. Selecting a reputable and reliable manufacturer can save you from issues like leakages, poor performance, and frequent replacements.

This guide will walk you through the key factors to consider when choosing a UPVC pipe manufacturer, helping you make an informed decision.

- Quality and Certification Standards

The first and foremost factor to evaluate is whether the manufacturer follows international and national quality standards. High-quality UPVC pipes must comply with industry certifications such as:

- ISO 9001 – Quality Management System

- IS 4985 – Indian Standard for UPVC pipes used in potable water supply

- ASTM D1785 – American Standard for UPVC pipes for water distribution

- BS EN 1329 – European Standard for UPVC drainage pipes

A manufacturer that adheres to these certifications and quality standards ensures that their products are safe, durable, and reliable.

- Manufacturing Technology and Process

The technology and processes used in manufacturing UPVC pipes play a significant role in determining their strength and longevity. Consider manufacturers who utilize modern extrusion techniques and automated production lines to maintain consistency in quality. Look for:

- Precision in wall thickness and dimensions

- Advanced resin formulation to enhance UV resistance

- Rigorous quality checks and testing protocols

A state-of-the-art manufacturing facility ensures that UPVC pipes meet industry demands for high performance and long-term sustainability.

- Raw Material Quality

The durability and performance of UPVC pipes largely depend on the quality of raw materials used. A good manufacturer sources premium-grade virgin PVC resin rather than recycled materials, which can compromise strength and longevity. High-quality raw materials ensure:

- Better resistance to corrosion and chemicals

- Smooth internal surface for efficient fluid flow

- Longer lifespan with minimal maintenance

Always inquire about the source and composition of raw materials before making a purchase decision.

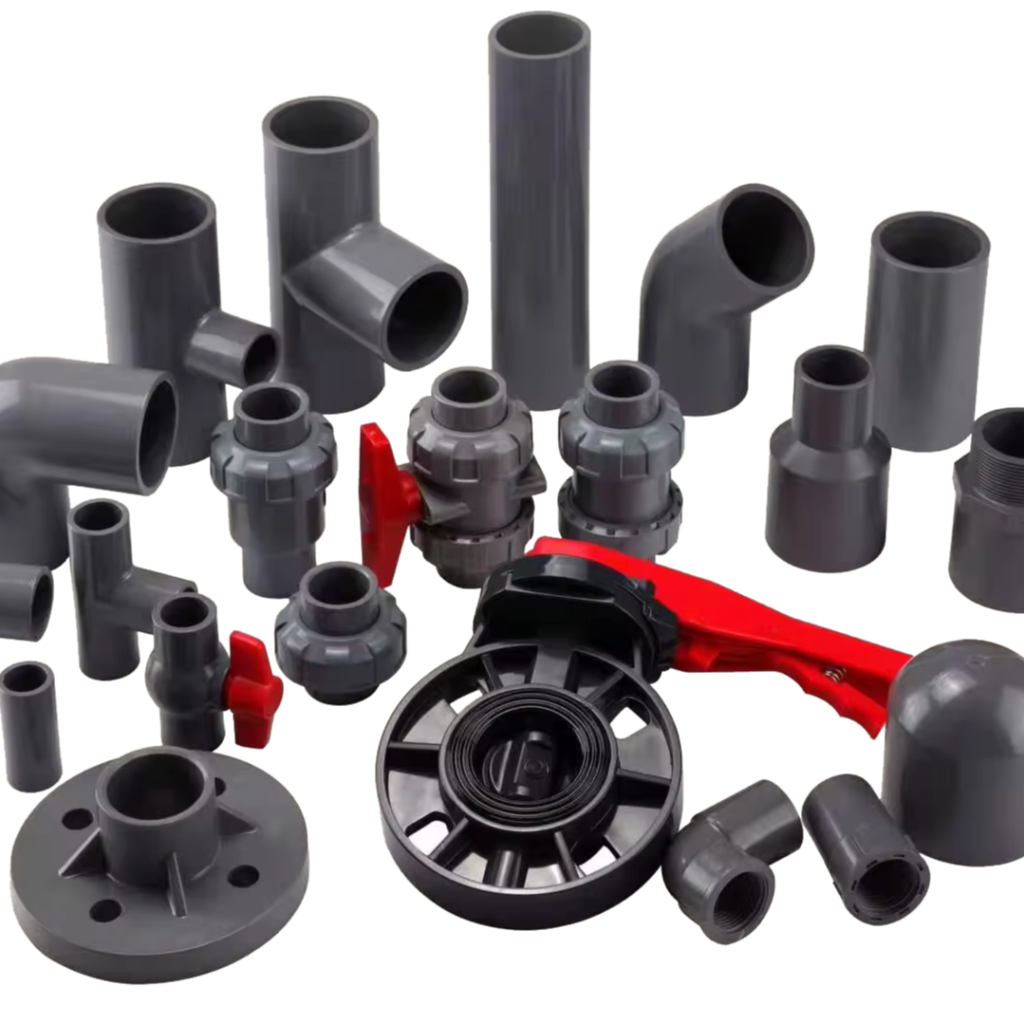

- Product Range and Customization Options

A reliable manufacturer should offer a comprehensive range of UPVC pipes and fittings to meet diverse application needs. Check if the manufacturer provides:

- UPVC pressure pipes for water supply

- UPVC plumbing pipes for residential and commercial use

- UPVC drainage pipes for sewage systems

- Customized UPVC pipe solutions for specific industries

Customization in terms of pipe diameter, thickness, and length ensures that you get the right product tailored to your project requirements.

- Strength, Durability, and Performance

The mechanical and chemical properties of UPVC pipes are essential for their performance in different environments. A high-quality UPVC pipe should:

- Withstand high pressure without cracking

- Resist chemical corrosion and UV degradation

- Have a long service life (over 50 years) with minimal maintenance

- Offer high impact strength for underground applications

Always request test reports or product samples to assess the durability and performance of the pipes before making a bulk purchase.

- Pricing and Cost-Effectiveness

While price should not be the sole deciding factor, it is essential to compare the cost-to-quality ratio of different manufacturers. Beware of extremely low-priced products, as they may compromise on raw materials and production quality. A reputed manufacturer provides:

- Competitive pricing without sacrificing quality

- Bulk purchase discounts for large-scale projects

- Transparent pricing with no hidden costs

Investing in high-quality UPVC pipes from a trusted manufacturer can help you save on long-term maintenance and replacement costs.

- Industry Experience and Reputation

Experience matters when it comes to manufacturing high-quality UPVC pipes. Look for manufacturers with:

- Decades of experience in the plastic piping industry

- Strong market presence and a proven track record

- Positive reviews and testimonials from clients

- Successful projects across different industries

A manufacturer with a good reputation is more likely to provide reliable and high-performance products.

- Testing and Quality Assurance

A reputable UPVC pipe manufacturer conducts rigorous quality testing before delivering products to the market. Some critical tests include:

- Hydrostatic Pressure Test – Ensures that pipes can withstand high pressure without bursting

- Tensile Strength Test – Measures resistance to pulling forces

- Impact Resistance Test – Determines the pipe’s ability to handle external shocks

- Chemical Resistance Test – Confirms non-reactivity to various chemicals

Ask for test reports or third-party certifications to verify product quality before making a bulk order.

- Supply Chain and Delivery Capabilities

Timely delivery of UPVC pipes is crucial for large-scale construction and industrial projects. A good manufacturer should have:

- A well-established distribution network

- Sufficient production capacity to meet bulk orders

- On-time delivery and logistics support

Make sure the manufacturer can handle urgent orders and maintain stock availability to avoid project delays.

- After-Sales Support and Warranty

Customer support is a key aspect when choosing a UPVC pipe manufacturer. A reliable manufacturer offers:

- Technical assistance for product selection and installation

- Product warranties for defects or performance issues

- Responsive customer service for inquiries and complaints

A manufacturer that stands by their product quality instills confidence in buyers and ensures a smooth purchasing experience.

Conclusion

Selecting the right UPVC pipe manufacturer is essential for ensuring high-quality, durable, and cost-effective piping solutions. By considering factors like certification standards, raw material quality, manufacturing technology, durability, pricing, and after-sales support, you can make an informed decision that meets your project’s requirements.

For industries looking for trusted UPVC pipe manufacturers, conducting thorough research and evaluating these key factors will ensure that you choose a manufacturer that delivers superior quality and long-term reliability.

Looking for a Reliable UPVC Pipe Manufacturer?

Ensure you partner with an industry leader that meets all quality standards and offers the best solutions for your piping and plumbing needs!