In the world of structural and industrial applications, the duplex square tube stands out as a reliable and versatile choice. These tubes are made from duplex stainless steel, which offers a unique combination of ferritic and austenitic steel characteristics. This dual-phase structure gives duplex square tubes their exceptional strength, excellent corrosion resistance, and enhanced durability, making them ideal for various industries such as construction, oil gas, marine, and chemical processing.

In this blog, we will dive into the features, benefits, applications, and advantages of duplex square tubes, while also helping you understand how to choose the right supplier for your needs.

What is a Duplex Square Tube?

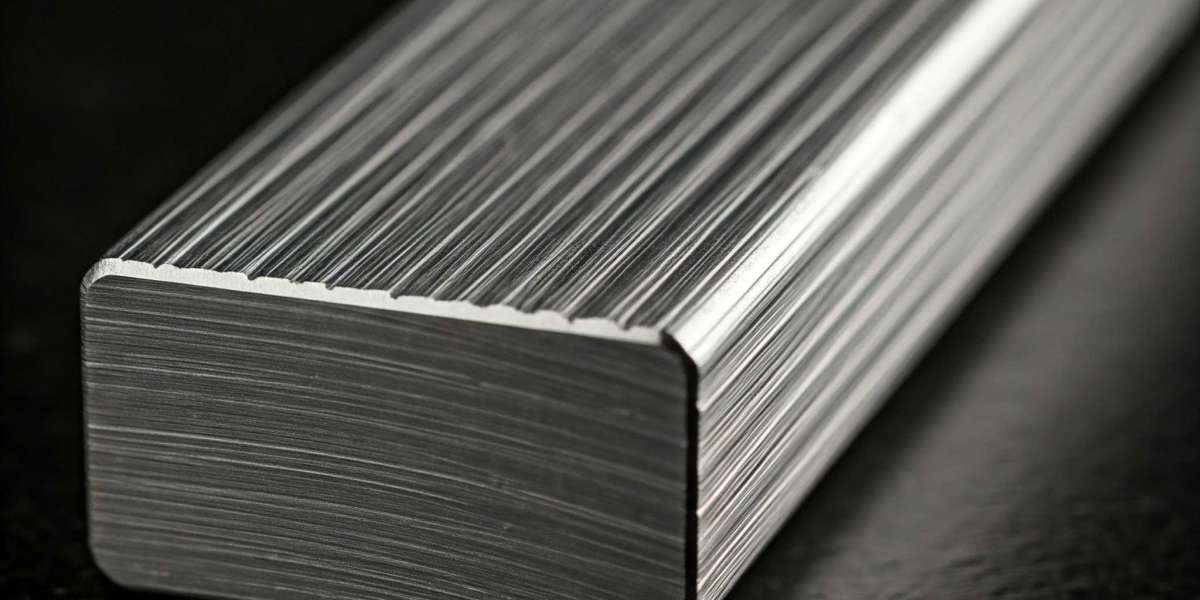

A duplex square tube is a tubular section with a square cross-section, made from duplex stainless steel, a material known for its superior strength and resistance to corrosion. Duplex stainless steel contains both austenitic (face-centered cubic structure) and ferritic (body-centered cubic structure) phases, usually in a 50:50 ratio. This unique microstructure results in a material that combines the best properties of both types of steel.

The most commonly used duplex grades for square tubes are UNS S31803 (2205), UNS S32205, and UNS S32750 (super duplex). These grades offer superior strength, better resistance to pitting and crevice corrosion, and excellent stress corrosion cracking resistance.

Key Features of Duplex Square Tubes

Duplex square tubes come with a variety of features that make them ideal for challenging environments. Below are some key attributes:

1. High Strength

One of the standout features of duplex square tubes is their superior strength. These tubes are typically twice as strong as austenitic stainless steel, making them suitable for demanding structural and mechanical applications.

2. Corrosion Resistance

Duplex stainless steel offers exceptional resistance to a wide range of corrosive environments, including chloride-rich environments, making duplex square tubes ideal for marine, chemical, and offshore applications.

3. Good Weldability

Despite their strength, duplex square tubes maintain good weldability. This property allows for easy fabrication and modification, making them suitable for a wide range of projects.

4. Stress Corrosion Cracking Resistance

Duplex stainless steel exhibits excellent resistance to stress corrosion cracking (SCC), which is particularly beneficial for applications in harsh environments, such as offshore platforms or chemical processing plants.

5. Cost-Effectiveness

While duplex stainless steel can have a higher initial cost than austenitic stainless steel, its durability and long service life reduce overall maintenance and replacement costs, making it a cost-effective choice in the long run.

Advantages of Duplex Square Tubes

Choosing duplex square tubes for your project comes with several notable advantages:

1. Improved Strength-to-Weight Ratio

Due to their high strength, duplex square tubes can be designed with thinner walls compared to other materials, reducing weight and material costs without compromising performance. This is especially beneficial in industries where structural integrity is crucial but weight needs to be minimized.

2. Enhanced Corrosion Resistance

Duplex square tubes provide superior corrosion resistance, especially in environments exposed to chlorides, such as marine or chemical industries. This makes them ideal for applications where exposure to saltwater or aggressive chemicals is a concern.

3. Long-Term Durability

The combination of high strength and corrosion resistance ensures that duplex square tubes last longer than many other materials, resulting in reduced maintenance and repair costs over time.

4. Versatility Across Industries

Due to their robust mechanical properties, duplex square tubes are used in a wide range of applications, from construction and architecture to oil gas and marine industries. Their versatility makes them a valuable material for various sectors.

5. Resistance to Stress Corrosion Cracking

Duplex stainless steel’s resistance to stress corrosion cracking is particularly valuable in high-pressure, high-temperature environments, ensuring the safety and longevity of piping systems and structural components.

Common Applications of Duplex Square Tubes

Thanks to their combination of strength, durability, and corrosion resistance, duplex square tubes are employed in various industries. Here are some of the most common applications:

1. Construction and Structural Support

Duplex square tubes are used in the construction industry for building frameworks, support structures, and other architectural elements. Their high strength-to-weight ratio allows for the design of lightweight but strong structures.

2. Marine and Offshore Industry

Marine structures, including ships, offshore platforms, and docking systems, often rely on duplex square tubes due to their exceptional resistance to seawater corrosion and overall durability.

3. Oil Gas Industry

In the oil and gas sector, duplex square tubes are commonly used for pipelines, risers, heat exchangers, and structural components. Their resistance to stress corrosion cracking makes them suitable for subsea and offshore operations.

4. Chemical and Petrochemical Industry

Duplex square tubes are widely used in chemical processing plants, where they are exposed to aggressive substances like acids, chlorides, and other corrosive chemicals. Their corrosion resistance ensures safe and efficient operation.

5. Pulp and Paper Industry

In the pulp and paper industry, duplex square tubes are used for various applications such as piping and structural components that need to withstand harsh chemical environments.

How to Choose the Right Duplex Square Tube Supplier

When selecting a duplex tube supplier, it’s essential to consider several factors to ensure you receive the best quality products and services for your project:

1. Material Certifications and Compliance

Make sure the supplier provides the necessary certifications such as EN 10204 3.1 or 3.2, ensuring that the duplex square tubes meet industry standards and quality requirements.

2. Customization Options

Choose a supplier that offers customization services such as custom lengths, diameters, and wall thicknesses to meet your specific project needs.

3. Reliability and Experience

Look for a supplier with a proven track record of delivering high-quality duplex stainless steel tubes and a solid reputation in the industry. Their experience can make a significant difference in product quality and service.

4. Competitive Pricing and Timely Delivery

Ensure the supplier offers competitive pricing while maintaining high standards of quality. Also, inquire about delivery timelines to make sure your project stays on schedule.

Conclusion

Duplex square tubes offer a high-performance solution for a wide range of industrial and structural applications. With their remarkable strength, resistance to corrosion, and stress corrosion cracking, duplex square tubes are a versatile choice for industries such as construction, marine, oil gas, and chemical processing.