These gauges are widely used in manufacturing, aerospace, automotive, oil gas, and construction industries to ensure quality control and compliance with safety standards.

In this guide, we’ll explore what a Wall Thickness Gauge is, how it works, its key benefits, and how to choose the right one for your needs.

What Is a Wall Thickness Gauge?

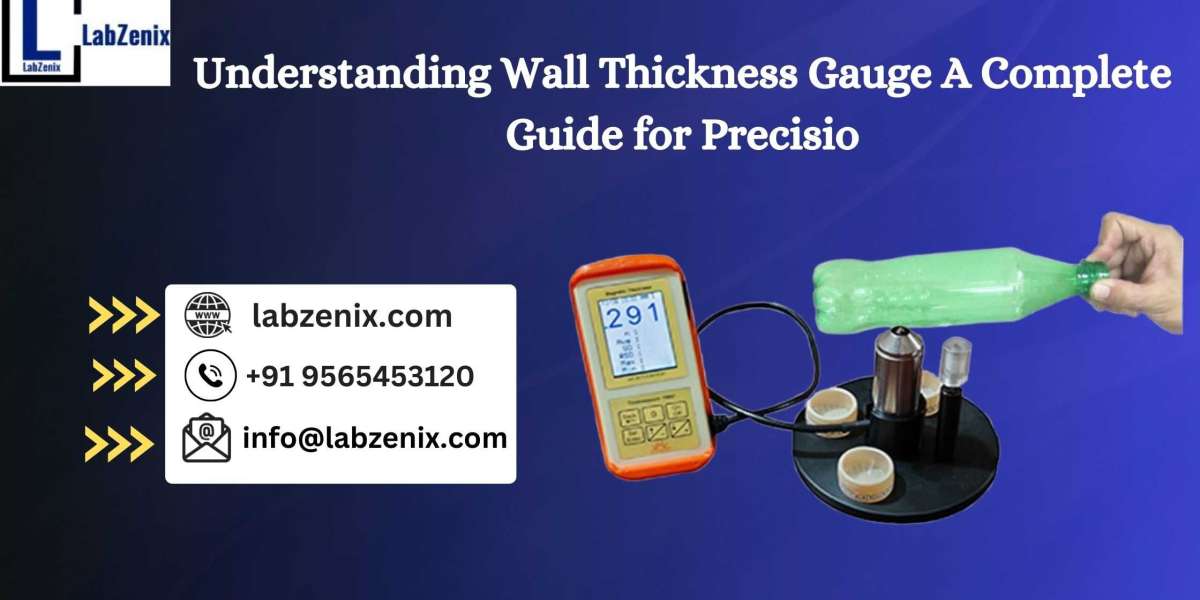

A Wall Thickness Gauge is a non-destructive testing (NDT) device designed to measure the thickness of materials such as metals, plastics, glass, and composites. It helps detect material thinning due to corrosion, wear, or defects, ensuring product reliability and safety.

How Does a Wall Thickness Gauge Work?

Most wall thickness gauges use either ultrasonic technology or magnetic induction:

- Ultrasonic Thickness Gauges: Emit high-frequency sound waves that travel through the material and measure the time taken for the echo to return.

- Magnetic Induction Gauges: Use a probe with a magnetic field to measure the thickness of non-magnetic coatings on ferrous materials.

Key Applications of Wall Thickness Gauges

Wall thickness gauges are used in various industries, including:

✔ Manufacturing: Ensures consistent product quality and thickness specifications.

✔ Aerospace Automotive: Checks the integrity of aircraft and vehicle components.

✔ Oil Gas: Detects corrosion and erosion in pipelines and tanks.

✔ Medical Healthcare: Measures the thickness of medical devices and implants.

✔ Construction: Evaluates the durability of building materials.

Benefits of Using a Wall Thickness Gauge

- Non-Destructive Testing (NDT): No need to cut or damage materials.

- Precision Accuracy: Provides reliable measurements within microns.

- Time Cost Savings: Reduces inspection time and prevents costly repairs.

- Enhanced Safety: Detects potential weaknesses before structural failure occurs.

How to Choose the Right Wall Thickness Gauge

When selecting a wall thickness gauge, consider:

✅ Material Type: Choose a gauge suitable for metals, plastics, or composites.

✅ Measurement Range: Ensure the gauge covers your required thickness range.

✅ Accuracy Resolution: Look for high-precision models for critical applications.

✅ Portability: Handheld models are ideal for field inspections.

✅ Display Data Storage: Digital displays and data logging capabilities improve usability.

Conclusion

A Wall Thickness Gauge is a vital tool for industries requiring accurate thickness measurements without damaging the material. By choosing the right gauge for your application, you can enhance quality control, ensure safety, and extend the lifespan of critical components.

Looking for high-quality Wall Thickness Gauges? Explore our collection at Labzenix.com and find the perfect solution for your inspection needs.